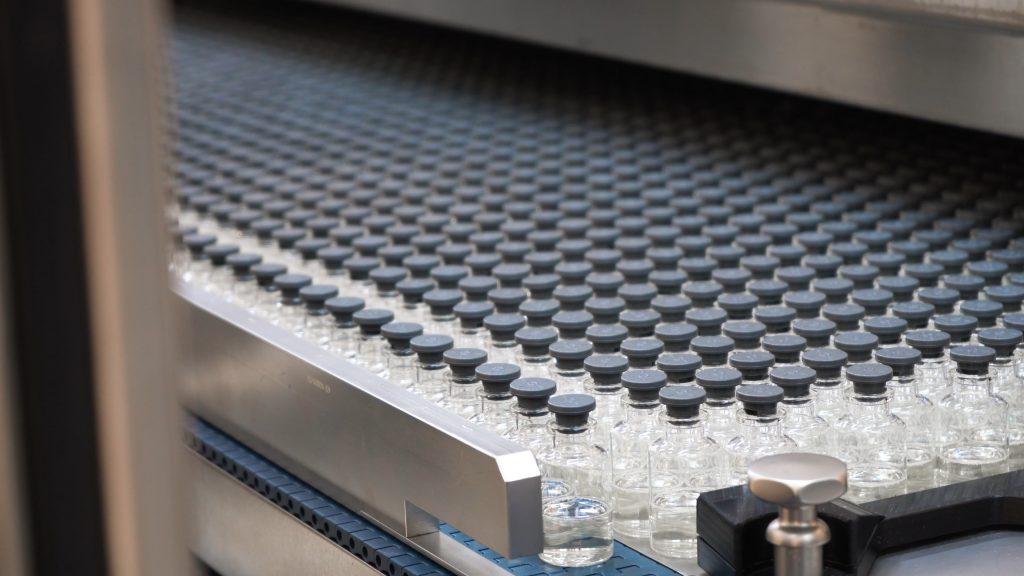

We also have experience with lyophilizing products within a syringe which can reduce costly waste from hold-up volumes. All filling operations and transfer to the lyo are performed in permanently connected isolators.

Lyophilization Details:

- Container Sizes: Client Directed

- Capacity: Client Directed – up to 31,500 10 mL vials

- Operations: Manual, Semi-Automated, or Automated – all

- Components: Client Specified

- Fully isolated filling environments

- Lyo development and optimization services

Need Development?

Unlock the full potential of your lyophilization process with our expert guidance. Whether you need development, optimization, or a seamless transfer, we are here to give you the best product and experience possible.

Our dedicated team ensures a water-free, high-quality cake in a fast cycle time.

Semi-Automated Filling Line

Semi-Automated Vial Filling & Lyophilization

Our semi-automated isolator-based fill and lyophilize up to 3,500 10R vials. This line is ideal for clinical-scale lyo projects.

Processing Modes

Automated Filling Line

Automated Vial Filling & Lyophilization

Our automated filling line can lyophilize up to 31,500 10R vials, and the line will be fitted with a second lyophilizer to double capacity by 2025. This line features fully robotic and automated filling in isolators to offer the greatest sterility assurance achievable.